| Outline (Upper) and Photograph (Lower) of the Equipment |

|

|

| Outline of Nanoparticles Production Equipment |

This nanoparticles production equipment is basically a sort of DC arc furnace.

In 1980s, an unique phenomenon, in which metals arc-melted in an atmosphere of gas including hydrogen evaporate very easily, and their evaporation rate in the atmospheric pressure(0.1MPa pressure) is larger than in a normal reduced pressure(0.01MPa), was discovered by Uda, Ohno, and Okuyama in the National Research Institute for Metals (now National Institute for Materials Science). Since then, it has been demonstrated that nanoparticles of many metals, alloys, and ceramics were manufactured in a modified DC arc furnace.

The nanoparticles are generated at the same time when massive materials are arc melted in an atmosphere (atmospheric pressure) of argon (also inert gas available) containing hydrogen (possibly, nitrogen or oxygen). On the other hand, the generation of the particles is stopped when the discharge is suspended. Hydrogen gas forcedly vaporizes these materials. For this reason, a hydrogen concentration in the atmosphere is increased proportionately with a rate of nanoparticles generation.

Attotec Co., Lt., has developed a new nanoparticles manufacturing system, or the only machine in the world, jointly with the above scientists having rich experiences and know-how in the field of arc melting.)

|

| Illustration and Photo of Nanoparticles Production by Our Process |

|

The right is one of video photos when Nb metal was arc-melted in an atmosphere of 50% H2-Ar (1 atm pressure)).The arc shows a pink color peculiar to hydrogen plasma. Metal vapor (Nb) shows a pale color (right).This metal vapor issues immediately on the side of the hydrogen plasma. This indicates that a Nb metal is forcedly vaporized by hydrogen and is compose to nanoparticles.

This forced evaporation is applied in a wide range of materials such as metals, alloys, and ceramics.

|

| Energy-saving and Pollution-free Preparation |

|

Nanoparticles released in the atmosphere of hydrogen-argon are carried to a collector (filter) away from a source chamber by gasflow for gas circulation. Hydrogen-argon gas producing nanoparticles is returned to the source chamber by a circulation pump and repeatedly used.

|

| 1. |

The nanoparticles manufacturing system consumes only a small amount of gas that is circulated and filtered, and generate no by-products. The machine realizes a pollution-free process. |

| 2. |

Any shape (block, plate, line, grain, etc.) of raw materials can be used for formation of nanoparticles. |

| 3. |

The system manufactures nanoparticles through forced evaporation. For this reason, it consumes power for evaporation of materials in two orders of magnitude smaller than conventional manufacturing equipment, and accomplishes an energy-saving process. |

|

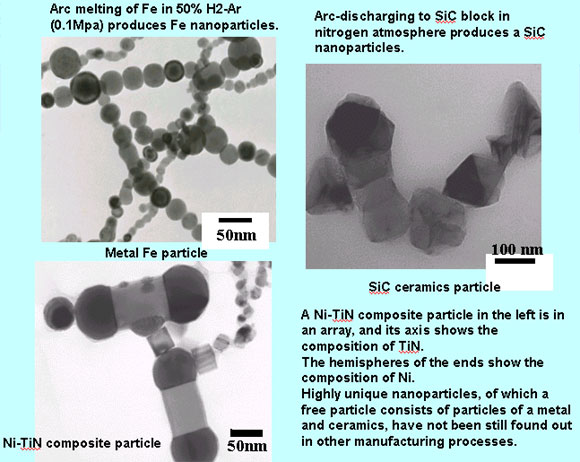

| Photo of Nanoparticles Obtained through this Process |

|

| Technological Comparison |

|

New Technology by arc plasma method |

Conventional technology by inert gas deposition method |

| Heating process |

Arc-discharge heating |

High-frequency induction heating |

| Atmosphere gas |

Hydrogen |

Argon |

| Atmosphere pressure |

Atmospheric pressure (100 kPa) |

Low pressure (1kPa) |

| Collection process |

Collection by filter |

Collection of particles adhesive to the inner wall of the system |

| Rate of nanoparticles generation |

High |

Low |

|

| Assumed Application |

| Nano material |

Metal, alloy, nitride, oxide, composite nanoparticles, etc. |

| Optical material |

Solar battery, photoselective paint, optical fiber, pigment, etc. |

| Magnetic material |

Magnetic recording material, magnetic fluid, electromagnetic shielding material, etc. |

| Catalytic material |

Hydrogenation catalyst, chemical heat pump, gas sensor, etc. |

| Sintering material |

Sintering additive, heat/substance exchange membrane, microporous filter, etc. |

| Electronic material |

Conductive/resistant pastes, various thick film elements, etc. |

|

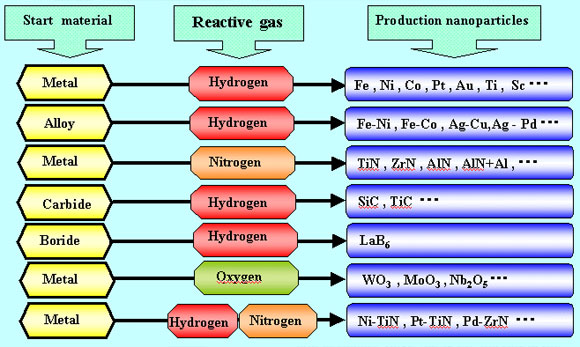

| Possible Preparation of Diversified Nanoparticles |

| This one system can manufacture a wide variety of nanoparticles of metals, alloys, and ceramics. |

| 1. |

Most of metals are arc-melted in an atmosphere of hydrogen and decomposed to nanoparticles. (e.g., Mg, Sc, Ti, Zr, V, Nb, Ta, Cr, Mo, W, Mn, Fe, Co, Ni, Pd, Pt, Cu, Ag, Au, Zn, Al, Si, Ge, Sn, Pb, La, Nd, etc.) |

| 2. |

Most of alloys are decomposed to nanoparticles in the same way as the metals.

Some types of alloys have a difference between the alloy and nanoparticles compositions. |

| 3. |

In creation of a composite particle, a combination of gas types and materials to be used may bring about a new type of nanoparticles. For instance, one composite nanoparticles (Ni-TiN) with a combination of a metal (Ni) and ceramic (TiN) is a new material that does not occur naturally. This system can produce this material. |

|

| Various Nanoparticles production by this process |

|

|

Various nanoparticles like the metal, ceramics or the mixture and the compound, etc. are obtained by combining the material and the reactive gas.

|

| Attention-getting New Product |

| Main Specification |

| Product name |

Type |

Specification |

| Nanoparticles |

Water-cooled jacket (SUS 304) |

Lateral hemicone type

1) Water-cooled electrode (with W tip)

2) Nanoparticles heat exchanger 1

3) Reacher

4) Spare port 3

5) Safety valve 1

6) Windows for monitoring and illumination |

| Glove box |

(SUS) |

1) Glove one pair

2) Sight glass

3) Transport

4) Nanoparticles collection container

5) Nanoparticles carrier pipe |

| Vacuum pump |

GHP-240B 1 |

Exhaust velocity 242 L/min |

| Circulation pump |

APN-P450 NSTX-1 Special type 2 |

Air flow rate 100 L/min

Maximum discharge pressure 0.1 Mpa |

| Diaphragm vacuum gauge |

ST-1DB 1 |

0.13 Pa - 13.3 Pa |

| Power supply for arc plasma |

Optional |

Power 300 A |

|

Interior of Generating Chamber in Nanoparticles Manufacturing System.

All parts of the generating chamber are designed to produce and collect nanoparticles with a high degree of efficiency.

Example:

Position where career gas is discharged

Simple and easy operation

Improvement of electrode position,

etc.

Interior of Generating Chamber in Nanoparticles Manufacturing System.

All parts of the generating chamber are designed to produce and collect nanoparticles with a high degree of efficiency.

Example:

Position where career gas is discharged

Simple and easy operation

Improvement of electrode position,

etc.

|

|